Advanced engineering and manufacturing excellence

Lancashire’s advanced engineering and manufacturing (AEM) sector is a cornerstone of the county’s economy. It demonstrates resilience, innovation, and global competitiveness, playing a critical role in driving productivity, exports, and sustainable growth. The sector also supports regional wellbeing and provides high-value employment across the county.

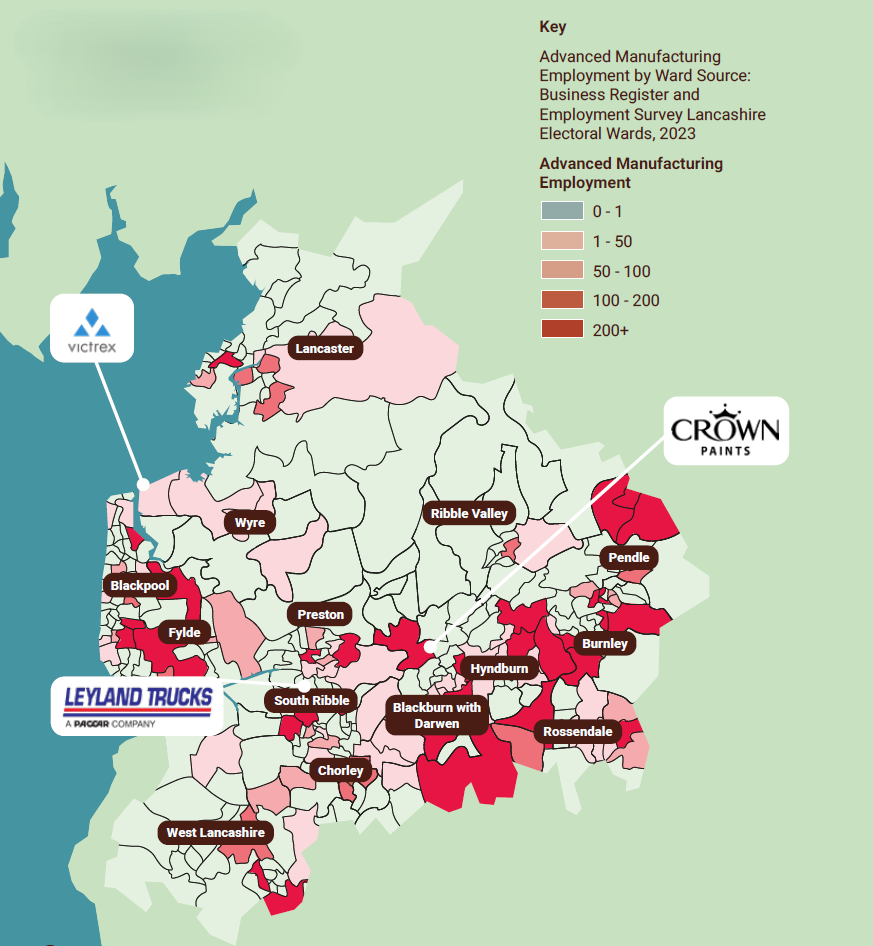

Employment levels in AEM have remained stable and are growing in parts of Lancashire, with productivity and output rebounding strongly post- COVID. East Lancashire, in particular, is a hub for advanced engineering and manufacturing, with major employers such as Safran in Burnley and Rolls-Royce in Barnoldswick anchoring a dense network of supply chain businesses.

Key industries include defence and civil aerospace, energy, chemicals, and commercial vehicles. Beneath these prime contractors is a robust ecosystem of mid-cap companies that have demonstrated adaptability, innovation, and a readiness to diversify into emerging low-carbon markets.

Sectoral strengths and specialisms

Electech Innovation Cluster

Established in 2020, the Electech Innovation Cluster includes over 50 members across North Lancashire and South Cumbria. The cluster supports growth in the electronics sector through collaboration, innovation, and engagement with universities via Knowledge Transfer Partnerships. Since its inception, the cluster has grown by 68%, with a combined turnover of £161 million and over 900 employeesxvi.

Energy and low carbon technologies

Lancashire’s AEM base is supported by the RedCAT network and is increasingly aligned with the energy transition, positioning the region as a national leader in clean growth. Between 2030 and 2050, Lancashire is forecast to have the highest number of energy and low carbon jobs per capita in England.

Lancaster University is investing £57 million in campus decarbonisation, including a solar PV farm and a new Low Carbon Energy Centre. Its Centre for Global Eco-Innovation has supported over 700 SMEs between 2012 and 2023, delivering measurable environmental and economic benefits.

Edge Hill University’s SustainNET initiative supports grassroots organisations through skills development and behaviour change programmes, critical to the success of local net zero and sustainability efforts.

AMRC North West has worked with nearly 600 Lancashire manufacturing SMEs since 2019, helping them adopt new technologies, improve processes, and reduce emissions. Its Additive Manufacturing Forum, launched in 2025, is building a local supply chain to retain high-value production, such as defence components, within the county.

The University of Lancashire’s Engineering Innovation Centre (EIC) in Preston is a £30 million plus hub for advanced engineering and low carbon innovation. Through applied research, industry collaboration, and workforce development, the EIC plays an important role in accelerating Lancashire’s transition to a low carbon economy.

Health innovation

There is growing synergy between AEM, digital, cyber, and health innovation. Opportunities in MedTech, robotics, and AI are emerging, with potential for cross-sector knowledge transfer from nuclear and defence into health applications.

Key locations and infrastructure

Lancashire’s AEM Corridor includes some of the UK’s most significant industrial sites:

- BAE Systems at Warton and Samlesbury – supporting key defence programmes such as Eurofighter Typhoon and F-35 Lightning II aircraft

- Safran Nacelles, Burnley – supporting civil aircraft engine programmes with carbon fibre reinforced composite systems

- Rolls-Royce, Barnoldswick – supporting civil and military aircraft engine programmes with metallic engine systems and components

- AGC Chemicals Europe and Victrex, Hillhouse Enterprise Zone – producing advanced materials for aerospace, defence, and EVs

These assets form one of the world’s largest aerospace and defence clusters, with Lancashire having the highest density of aerospace and defence employment in the UK, accounting for 1 in every 45 jobsxvii.

Additional key sites include:

- Hillhouse Enterprise Zone, Lancaster – with potential for hydrogen production, waste-to- energy, and nuclear-related manufacturing

- Westinghouse, Springfields, Fylde – a global leader in nuclear fuel manufacturing

- Emerson & Renwick, Accrington - a world- leading equipment engineering company

- Graham Engineering, Nelson – specialising in high-integrity components for nuclear, aerospace, and defence

- Perspex, Darwen – a leading acrylic sheet manufacturer

Advanced engineering and manufacturing

Strategic role and economic importance

A team of industry and academic specialists working on the Lancashire Advanced Engineering and Manufacturing Watchtower Programme, supported by Lancashire County Council, have identified numerous new growth opportunities for Lancashire manufacturers over the next decade. These include:

- The Global Combat Air Programme (in collaboration with Italy and Japan)

- The AUKUS Submarine Programme (in collaboration with the United States and Australia)

- Small Modular Nuclear Reactors (SMRs)

- Zero Emission Heavy Goods Vehicles (electric and hydrogen powered)

- Gigafactories

- Space Technologies

These initiatives could provide high-value employment for tens of thousands of people in Lancashire by 2035, contingent on improvements in the skills, productivity, and competitiveness of local supply chains.

These growth opportunities complement the traditional aerospace and automotive manufacturing sectors in Lancashire, which also have significant growth forecasts. For instance, the global aerospace industry delivered 1,128 new aircraft in 2024 and received 1,447 new orders. As of early 2025, there were 15,818 aircraft on backlog order - equivalent to thirteen years’ worth of work at current manufacturing ratesxviii.

Space sector expansion

Lancashire is well-positioned to capitalise on emerging opportunities in the space sector, particularly through the development of space batteries and advanced materials. Building upon the Altitude facility at Warton Enterprise Zone, there is significant potential to establish a regional hub for space innovation, supporting satellite technologies, propulsion systems, and low-earth orbit applications.

Case study: Victrex

Victrex develops high-performance polymer solutions used in electronics, automotive, aerospace, and energy industries. Their materials are found in over 20,000 aircraft, 500+ million automotive applications, and 100+ million industrial machines. The company has invested £90 million in a third production plant in Lancashire and is a cornerstone employer in the Lancashire Careers Hub, inspiring and engaging young people in local schools and colleges.

Growth Plan project supporting the AEM sector joining up innovation assets

Lancashire aims to maximise the impact of recent capital investments by developing complementary revenue-based initiatives. We will define a common set of revenue support activities and programmes that run alongside the capital investments. These will scale the economic potential of key innovation assets, such as AMRC North West and the University of Central Lancashire’s Engineering Innovation Centre (EIC). These propositions are designed to attract further public and private investment, support high-value job creation, and ensure long- term, inclusive economic benefits.